Will Not Prime

SYMPTOMS:

When first started, pump will not discharge fluid after a reasonable operating time.

THEORY OF CAUSE:

When a positive displacement pump with no fluid in its pumping chamber is first started, the pumping chamber contains only air. In order to fill the pumping chamber with fluid (prime) so that it can generate pressure, it must be able to "pump" enough air to create a partial vacuum in the chamber. This reduced pressure permits the atmospheric pressure in the fluid reservoir to force the fluid into the chamber and permit fluid pumping to start.

If the fluid supply is located "above" the pump inlet, then there is a positive pressure due to the weight of fluid (positive suction head) that makes priming easier. If the fluid supply is "below" the pump inlet (negative suction head), then enough air must be evacuated from the pumping chamber to overcome the weight of the fluid and "raise" it to the level of the inlet to the pump.

Plunger pumps are not very efficient as a "vacuum pump", especially the higher ratio pumps that have a relatively small displacement compared to their actual chamber volume. For this reason, the outlet pressure should always be "atmospheric" (unblocked) when priming. Any resistance downstream will make "air pumping" difficult or impossible, thus preventing proper priming of the pump.

TROUBLE SHOOTING CAUSES:

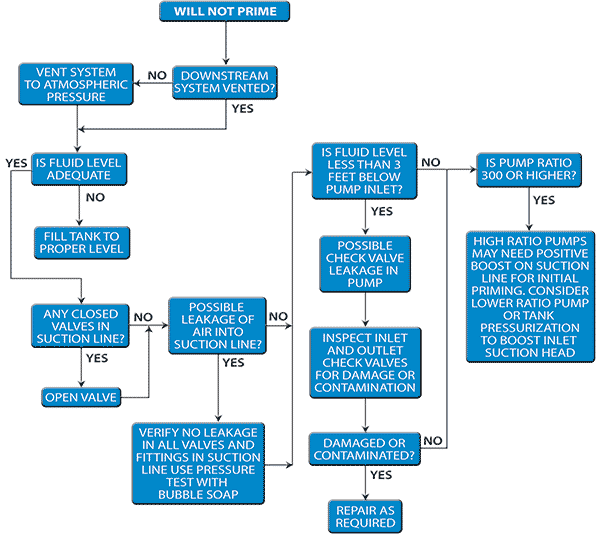

The following items should be checked to verify the cause of not priming. The order given is a logical progression that will minimize dis-assembly and/or testing.

a. Check to verify that the outlet of the pump is unrestricted. It is usually a good idea to have a valve that is located downstream of the outlet that is connected back to the supply tank. This valve can be opened during startup, and closed when the pump has achieved prime.

b. Check fluid level in the tank to make sure that it adequately covers the suction tube. Also, if the supply is located "below" the inlet, verify that the distance is not too great for the available suction on the pump. Each two feet of distance requires about 1 psi of vacuum in the pumping chamber in order to prime the pump. Since the vacuum capability is very limited, keep the distance to a minimum.

c. Verify that there is no closed valve in the suction line between the tank and the pump inlet.

d. A small air leakage at any connection in the suction line can permit enough air to enter so it would be impossible to pull an adequate vacuum for priming. Verify all connections are properly fastened and sealed.

e. Leakage of either the inlet or the outlet check valves can prevent the pump from priming, since it will make it even more difficult to provide the necessary vacuum. Check for any contamination or damage to the check valves after all the above items have been eliminated.

f. Providing a small positive pressure to the air space (ullage) at the top of the fluid tank will also help achieve prime, if the tank is designed with that capability.

g. For extremely high ratio pumps (300 ratio and higher), it is suggested that a lower ratio pump be used to supercharge the inlet to assist in priming. This will also minimize cavitation effects if the fluid supply must be located a significant distance below the pump inlet.