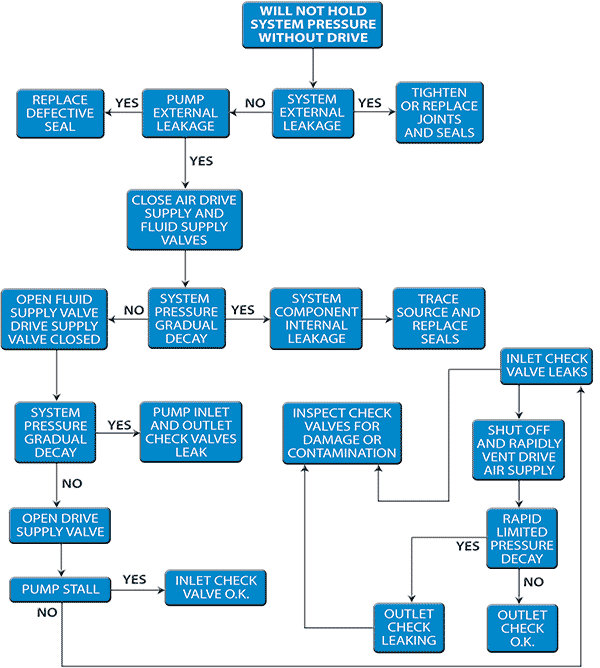

Will Not Hold System Pressure Without Drive

Venting drive pressure results in a sudden drop in system pressure and/or a steady decline in system pressure after the initial drop.

THEORY OF CAUSE:

In a "normal" situation with a "leak free" system and a "good" pump, the system pressure will have no significant decay when the pump is stopped and the air drive vented. The pump outlet check valve will prevent return of pump fluid, and a "leak free" system will prevent fluid loss. Pressure will remain relatively constant. Since fluid loss in the system CAN occur, it is necessary to eliminate that possibility before looking for pump problems. The following items can cause the condition:

a. System external leakage (loose or defective fittings)

b. System internal leakage (through valve seats, cylinder piston seals or relief valves)

c. Pump outlet check leakage (will cause sudden drop, but not continual decline in pressure, since only pump displacement is involved)

d. Pump outlet AND inlet check valve leakage (will cause sudden drop and continued decline as fluid leaks through both checks back to the fluid supply line.

TROUBLE SHOOTING METHODS:

Adjust air drive pressure to the value which will just barely maintain system pressure (stall).

Verify no external leakage of fluid at the pump and all system joints and components with the system maintained at operating pressure and the pump operational.

Shut off both the air drive pressure supply and pumped fluid supply valves. If the system pressure decays gradually, without stopping, then there is most likely an internal leakage in a system component. If there is no continuing decay, then the system is "tight" and the problem is most likely in the pump check valves.

If the system has been eliminated as a factor, open the fluid supply (air drive still shut off) and monitor system pressure. If the pressure starts a gradual decay, then both inlet and outlet checks are leaking.

If there is no decay, open the air drive pressure supply valve and allow the pump to come up to system pressure and stall. Shut off and rapidly vent the air drive pressure, monitoring system pressure. A rapid, limited drop in system pressure would indicate the pump outlet check valve is not sealing properly.