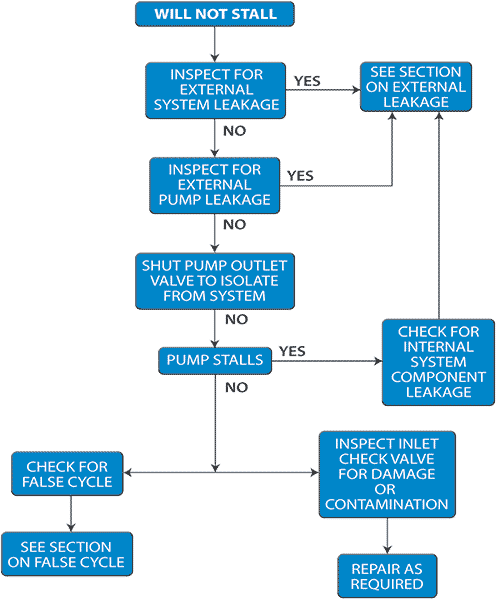

Will Not Stall

SYMPTOM: BOOSTER WILL NOT STOP CYCLING WHEN OUTLET IS BLOCKED OR STALL PRESSURE IS ACHIEVED.

THEORY OF CAUSE:

The reasons for a single or double acting booster to continue cycling after system shut-off or achieving stall pressure has been reached are as follows:

a. System leakage, (may be external or internal in a component).

b. Internal or external booster seal leakage.

c. False cycling of booster.

d. Maximum compression ratio has been exceeded.

When the booster has completed a suction stroke, it can only complete the cycle if it can "dispose" of the fluid. Since we are dealing with a compressible fluid, the options are a little different than with a liquid pump. The �disposal� can mean compression without generating enough pressure to open the outlet check valve against system pressure. This occurs when the �maximum compression ratio� is exceeded. The booster has a certain amount of �unswept volume� because of the need to account for tolerances and geometry of the parts. At the end of the compression stroke, this volume contains system pressure. On the suction stroke, after compression, this volume must expand to lower the pressure to less, than supply pressure in order to take in additional gas. If the stroke is insufficient to create this expansion, the booster will continue to cycle at a slow rate and re-compress the same charge of gas with no outlet flow.

For best operating efficiency, it is recommended that the actual compression ratio used in service be limited to 6:1. Any compression ratio, up to the maximum listed in the catalog, will give flow, but at a progressively decreasing amount. This will result in excess usage of drive air for the amount of gas transferred.

TROUBLE SHOOTING METHOD:

For item a, check the system shut-off valve or operational device (i.e.- cylinder, receiver, etc.) for possible leakage. The system should be eliminated as a source of the problem before trouble shooting the booster.

For item a. and b., see section on "Leakage"

For item c, see section on "False Cycling"

For item d. check actual compression ratio (outlet press+15/inlet press+15). Value must be less than specified maximum.